| 公司: | VLOT architecten | 类型: | 建筑 |

|---|---|---|---|

| 地区: | 荷兰 | 标签: | 构筑物 |

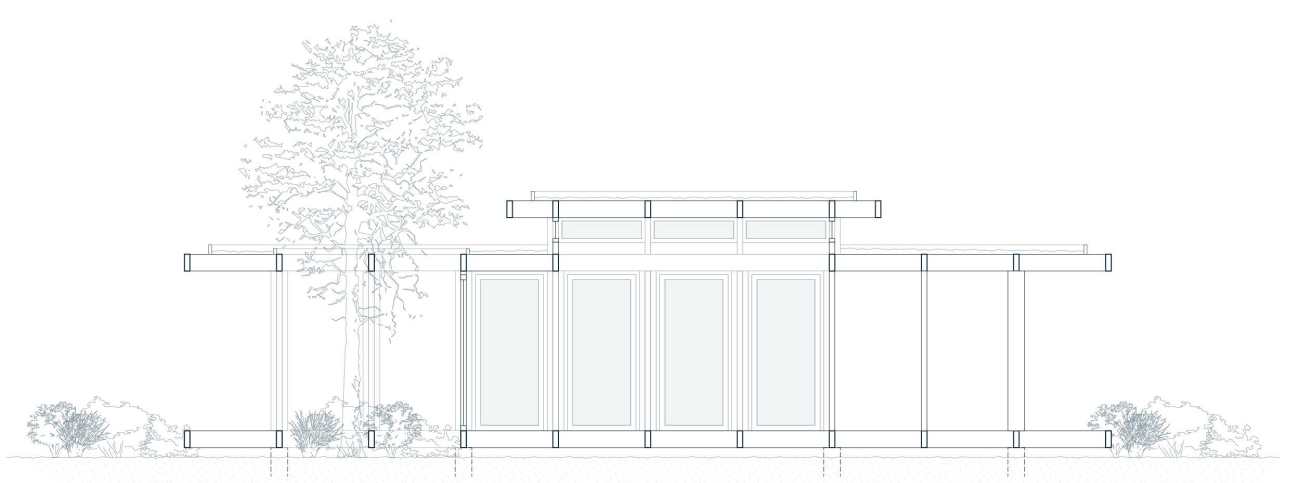

在堤坝和农田之间的花园里,VLOT architecten设计了一座小房子。客户的主要目标是创造一个地方,在那里他们可以享受花园农田的美景。木结构与周围的环境交织在一起,现有的植物和树木都被纳入结构中。整个玻璃幕墙可以打开,这样做是为了淡化内部和外部之间的边界,屋檐创造了一个渐进的过渡。

In a garden between a dike and farmland VLOT architecten designed a small house. The main goal of the clients was to create a place where they could enjoy the garden more as well as the view over the farmland. This is translated in a wooden structure that is interwoven with its direct surroundings. Existing plants and trees are incorporated in the structure. The entire glazed façade can be opened and in doing so is fading the border between the inside and outside. The cantilever adds to this and creates a gradual transition.

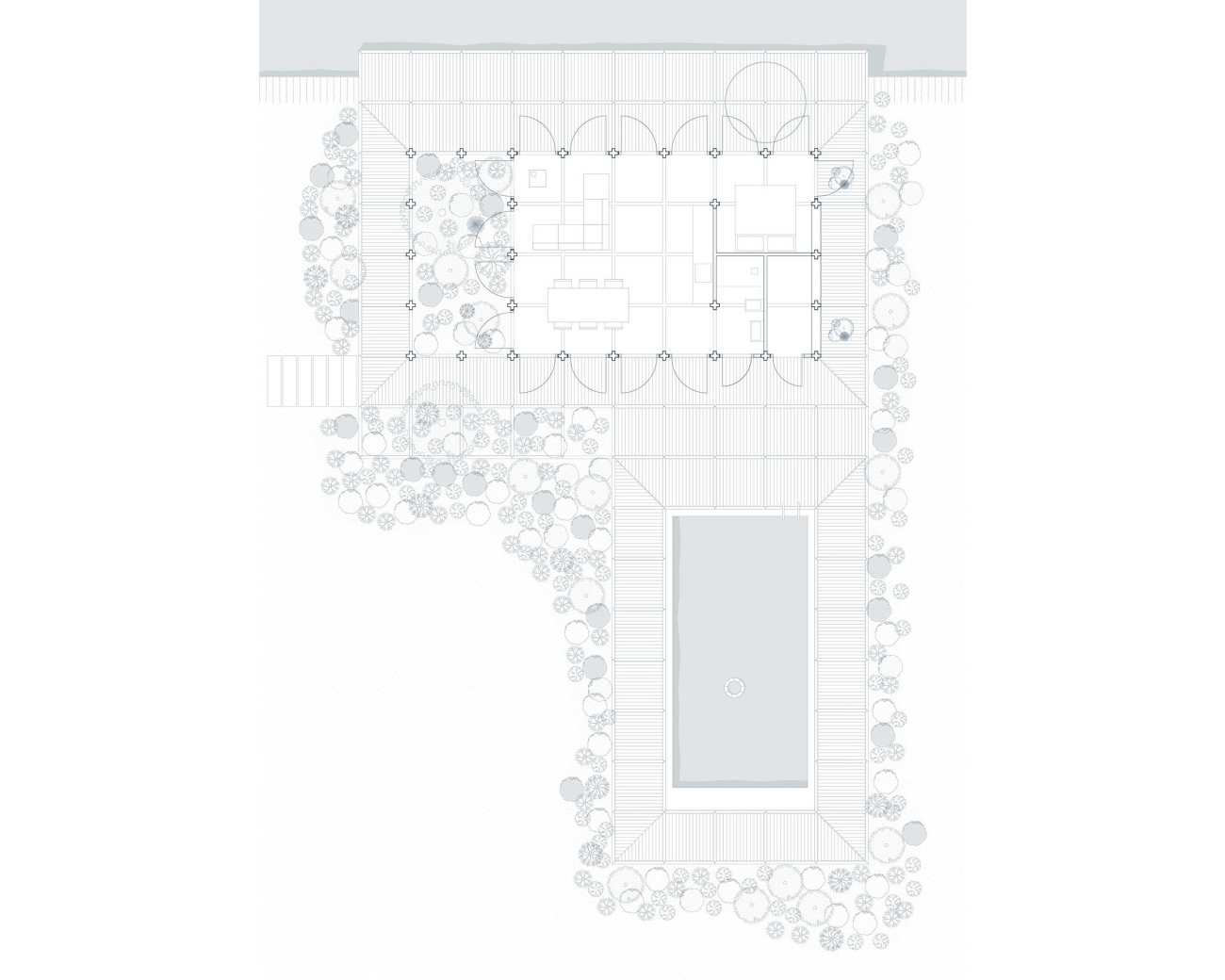

项目的面积为54平方米,但在天气允许的情况下,整个平台的面积可以扩大到210平方米。地面与花园之间的距离稍稍加高,这样一来,花园就会在露台下延续。甲板悬空在现有的沟渠上,这条沟渠形成了花园和农田之间的边界。从这个角度可以观察到不断变化的农田。凉棚与结构融为一体,从内部与花园建立了非常直接的关系。大部分的雨水通过屋顶引到凉棚,灌溉植物和树木。

Buitenhuis is 54 m2in size however, when the weather allows it, the entire deck can be experienced as surface area enlarging to 210 m2. The floor is heightened a little from the garden and in doing so the garden continues under the deck. The deck cantilevers over an existing ditch, this ditch creates the border between garden and farmland. From this vantagepoint the ever-changing farmland can be observed. The pergola is incorporated within the structure and creates a very direct relation with the garden from the inside. The majority of the rainwater is guided via the roof to the pergola and irrigates the plants and trees.

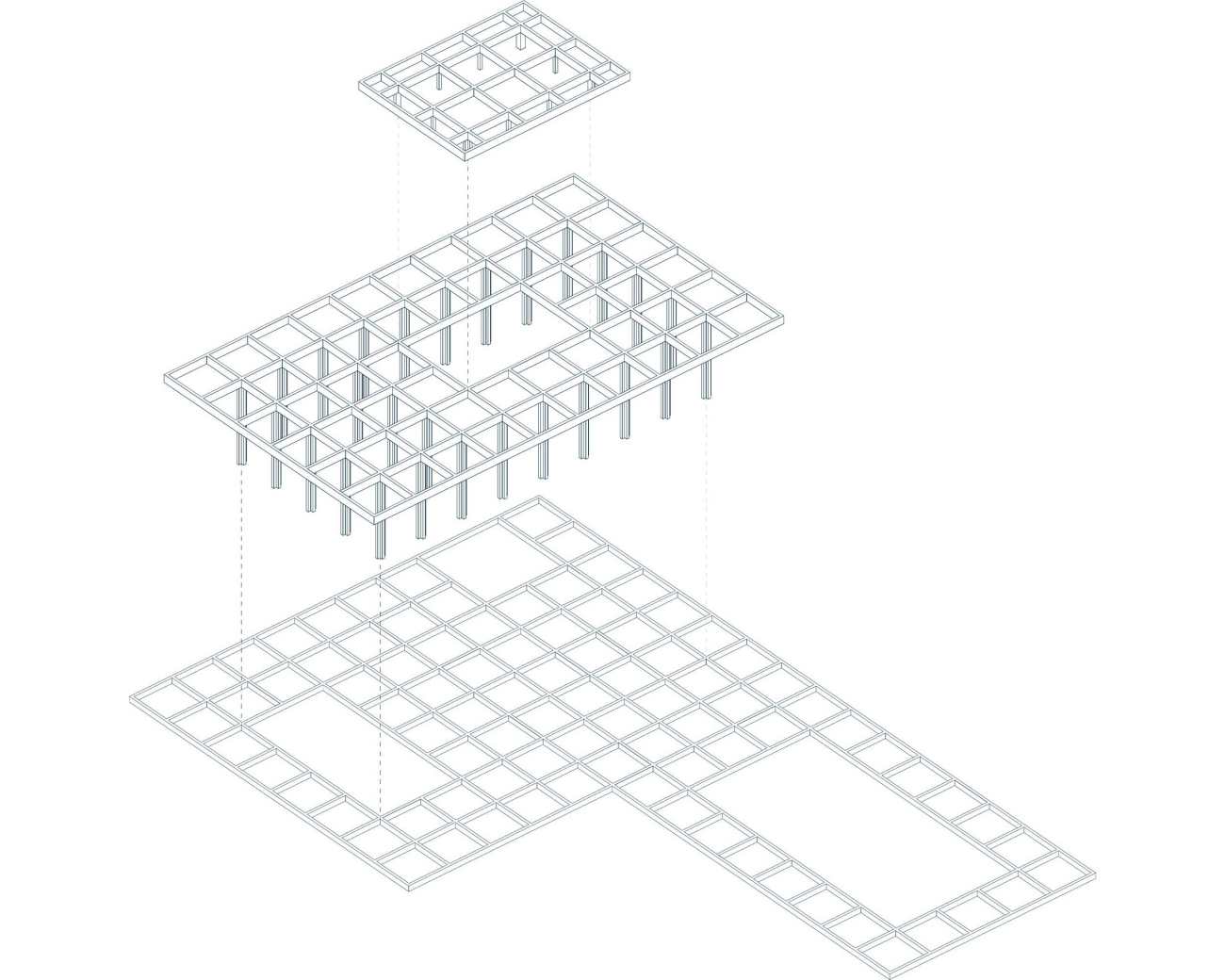

模块化

编制了叠层落叶松与CLT组合的结构。三面墙使柱梁结构具有稳定性。它是一个模块化的结构设计在一个1.5米的网格。十字形的柱子被放置在网格上,支撑着屋顶。模块化结构由6个预制构件组成。内层、外层、开立面、闭立面、内屋顶和外屋顶。该结构被有意地保留在某些地方,为植物和树木创造空间。

Modular

The structure is compiled of laminated larch combined with CLT. Three CLT walls give the column and beam structure its stability. It is a modular structure design on a 1,5-meter grid. Cross-shaped columns are placed on the grid and carry the roof. The modular structure is filled in with six prefabricated elements. The inside floor, the outside floor, the open façade, the closed façade, the inside roof and the outside roof. The structure is deliberately left unfilled in certain spots creating space for plants and trees.

▽结构轴侧分解图 Frame structure

木头,木头,木头

这座建筑是用木材建造的,以尽可能降低二氧化碳的影响。木材用作落叶松承重结构、落叶松窗框、带落叶松包层的木框架、木纤维绝缘、桦木胶合板地板和天花板以及花梨木装饰。屋顶覆盖着景天,既作为一个集水器,又作为建筑和自然的融合。建筑被设计成完全可拆卸的,只使用干连接。

Wood, wood, wood

This building is made with wood to keep the CO2 impact as low as possible. Wood is used as the larch load bearing structure, larch window frames, timber framing with larch cladding, wood fiber insulation, birch plywood floor and ceiling and padouk decking. The roof is covered with sedum, which works both as a water collector and as an integration of building and nature. The building is engineered to be completely dismountable, only dry connections have been used.

|  |

项目是采用全电资源的,采用电地暖,电锅炉和电烹饪。悬臂遮挡了夏天炎热的阳光,让冬天的阳光进来。屋顶的高度使热空气上升。玻璃立面可以从四面打开,这样风就可以通过。

Buitenhuis is all-electric and uses electric floor heating, electric boilers and electric cooking. The cantilevers keep the hot summer sun out and let the winter sun in. The elevation in the roof allows hot air to rise upwards. The glass façade can be opened from all sides so the wind can pass through.

没有承建商的建筑

这座建筑完全是用BIM模型设计的。现有的游泳池是现场测量的,这些物理坐标被用作数字参考。钢基础与木质承重结构的三维模型进行了多次同步、优化和互换。客户自己承担了承包商的角色,并将合适的分包商集合在一起。作为建筑师,VLOT负责按时订购所有必要的建筑材料。使用bim模式订购所有材料,尽可能减少浪费,现场几乎没有任何剩余材料。模块化设计允许大量的预制。在现场,完成的部件被放置到位。这是为承重结构,窗框,所有平台,地板和天花板做的。这些是在一个温暖干燥的车间里制作的,然后带到现场。

Building without a contractor

The building is completely engineered using a BIM-model. The existing swimming pool is measured on site, these physical coordinates were used as a digital reference. 3D models of the steel foundation and wooden load bearing structure have been synced multiple times, optimized and interchanged. The client took the role of contractor upon himself and brought fitting subcontractors together. As architects VLOT was responsible for the ordering all the necessary building materials on time. Using the BIM-model to order all the materials as little waste as possible was created, on site there was hardly any leftover materials. The modular design allows for a great deal prefabrication. On site the finished elements were put in place. This was done for the load bearing structure, window frames, all decking boards, floors and ceilings. These were made in a warm and dry workshop and then brought to site.

▽平面图 Plan

▽剖面图 Section

Project Name: Buitenhuis

Architecture Firm: VLOT architecten

Website:www.vlotarchitecten.nl

Contact e-mail:stefan@vlotarchitecten.nl

Firm Location: Delft, the Netherlands

Completion Year: 2020

Gross Built Area: 54m2

Project

location: Heinenoord, Zuid-Holland

Lead Architects: Jeroen Lemans and Stefan de Vos

Lead Architects e-mail: stefan@vlotarchitecten.nl

Design Team: Jeroen Lemans and Stefan de Vos

Clients: private

Engineering: Rutger Snoek, Transistor

Photo credits: VLOT architecten

更新日期:2020-11-09 16:40:09

非常感谢 VLOT architecten 带来的精彩项目, 查阅更多Appreciations towards VLOT architecten for sharing wonderful work on hhlloo. Click to see more works!